31 May Spanner Works: JP du Plessis

A regular feature, outlining the activities of FMM’s workshop personnel who are responsible for repairing, renovating, refurbishing and restoring the museum’s large and varied collection of vehicles. This month we report on JP getting into the saddle and gearing up his Mustang…

Everyone loves a ’60s Ford Mustang! It’s one of the most iconic sports cars ever built and the design has really withstood the test of time, and one of the museum’s examples is a 1968 Convertible. It has the 289ci (4 735cc) V8 coupled with a 3-speed manual gearbox. It is rare to find an American car with a manual gearbox, so this is a refreshing variation to the norm.

With age, of course, mechanical linkages and interfaces wear out and need to be fixed or replaced to function at an optimal level. In the case of this ’68 ragtop, the pedal assembly needed urgent attention. When driving, we would experience a clutch pedal stuck towards the floor, which then had to be awkwardly retrieved by hand! As you can imagine this is not an ideal task while driving…

Upon checking the pedal assembly in the workshop, it was found that the clutch pedal pivot shaft had worn through its bushes and the steel mounting bracket. This caused the shaft to misalign when depressing the pedal and get stuck in the mounting bracket. Removing this entire assembly was the only option, as it required some re-fabrication that would only be possible on a bench. This, however, was no mean feat and required patience, care and some more patience to get it out. Working inside a car, one has to always be careful not to damage any of the softer surfaces around you.

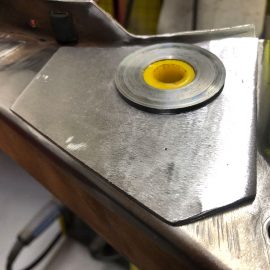

Once out, the entire pedal assembly was assessed on the bench and a plan of action was devised. First, the paint was stripped off the mounting bracket and the rust removed. This is the base of the pedal operation and needs to be aligned perfectly, and be strong enough to withstand the countless cycles of pedal depressions. So, gusset plate templates were drawn up on paper, measuring carefully to ensure alignment of holes. The paper templates were then fabricated in 3mm steel plate and welded onto the mounting bracket.

Then new, thicker cross-section metal top-hat bushes were turned on the lathe and welded into the holes on the mounting bracket, while keeping the inner diameters aligned as much as possible. With welding, metal always pulls to some extent, so one has to compensate for that when measurements are crucial. After the metal bushes, thicker nylon inner bushes were turned on the lathe. These are the ‘damper’ bushes that interface the pedal pivot shaft to its mounting bracket.

With all the parts fabricated and the metal items welded together, the bracket was repainted and the entire assembly rebuilt. It was time to refit the assembly to the Mustang to see if it would work as intended. Many hours of body contortions, sweat and tears later, it was ready to test. A little adjustment was required on the clutch cable, but otherwise nothing more was needed and the test drive proved the repair to be a success. A good, solid clutch action and – most of all – no sticking pedal!